PRODUCTS

Automatic casing machine

New energy large square heat shrink tubing machine

1. The baking device adopts a screw module transmission component combined with a closed-loop motor to achieve high-precision positioning baking, and its baking position can be adjusted digitally

2. The baking method uses double heating tubes to bake up and down, which not only has high work efficiency but also makes the baking more uniform

3. Digital temperature control and abnormal monitoring of heating devices. The pneumatic bottom heating device automatically protects and extends its service life

4. Prevent operator parameter adjustment errors and restore the system with one click

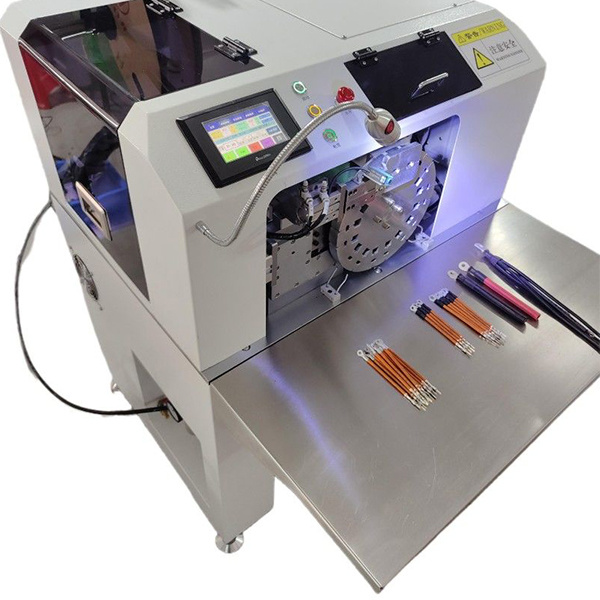

Fully automatic heat shrink sleeve printing terminal machine

1. The equipment mainly adopts original components from Taiwanese and Japanese brands, completing functions such as cutting wires, peeling, and terminal pressing, with precise movements and stable performance

2. The host is equipped with a four wheel synchronous wire feeder to maintain constant wire tension; Equipped with automatic terminal cutting strip device

3. Host motion control card control, Chinese and English touch screen parameter settings, short adjustment time, and easy operation

4. Suitable for horizontal and direct OTP terminal molds

5. Energy saving, space saving, and environmentally friendly equipment

Heat shrink tube automatic casing machine

1. Industrial automation PLC, human-machine interface control, simple operation, stable operation, and high efficiency

2. The heat shrink sleeve is automatically fed, and the hot melt length can be freely set, and the welding position can be adjusted through a positioning device

3. The production capacity can reach 700-2500 terminals per hour (depending on the manual online speed)

4. The equipment has high compatibility, and multiple specifications of line materials can be processed by replacing fixtures

Online coding and heat shrinking automatic all-in-one machine

Automatic printing of heat shrink tube labels, achieving printing of different labels on multi-core wires, automatic feeding and cutting of heat shrink tubes, and free setting of baking length with fixtures.