PRODUCTS

No mold replacement terminal machine

Hexagonal mold free hydraulic press WZ-Y150

1. The machine adopts electronic positioning to adjust the crimping Pressure altitude, and the crimping height of processing data can be directly adjusted on the screen, which is accurate and efficient

2. It can be assembled with hexagonal molds, open terminal molds, etc

3.16-150 square meter crimping does not require mold replacement, and is universal for one machine. It can pre store commonly used processing data with just one click on the screen to switch

4. All machines are pre stored with processing data of 16-150 square meters before leaving the factory, which can be adjusted according to actual needs

Hexagonal mold free hydraulic press

Product name: Hexagonal mold free hydraulic press

Equipment model: WZ-Y95

External dimensions: L500 * W350 * H940mm

Total weight: 150KG

Input power supply: AC220V/50Hz

1. This machine adopts electronic positioning to adjust the crimping pressure height. The crimping height of processing data can be adjusted directly on the screen, accurate and efficient. 2. Can assemble hexagonal die, open terminal die, etc. . 3.6-95 square crimping do not need to change the mold, a machine general, can be stored commonly used processing data, just click on the screen a key to switch. Four. All machines pre-store 6-95 square processing data, can be adjusted according to actual needs.

Rotary peeling and crimping machine WZ-540 for tubular pre insulated terminals

Function: rotary peeling, twisting, threading, crimping

Operation mode: automatic trigger operation and manual operation

Line size specification: suitable for BVR lines of 0.5, 0.75, 1.0, 1.5, 2.5, and 4.0 square meters

Peeling length: Peeling length 17mm

Electric four-sided crimping machine

1. Adopting a hybrid stepper motor, efficient subdivision driver, integrated circuit motherboard, high-quality mechanical components, and precise motion control

2. Capable of achieving four sided or four point crimping of wires below 4 square meters

3. Lightly touch the screen to directly input the crimping position and opening position

4. Equipped with two crimping modes, single step and automatic, to clearly interpret each step of the action

5. Data storage function, which can edit and store 20 different terminal crimping data

6. Color touch screen control, fast and accurate parameter input, and clear interface switching

7. Three positioning methods to ensure that the terminal crimping position is centered and not deviated

8. This machine has a pressure maintaining function, making crimping more stable and reliable

Multifunctional servo terminal machine WZ-5120

Terminals of different sizes are free of mold replacement, using variable frequency servo technology and electronic positioning, without the need for tool replacement. The size of the crimping blade can be changed instantly, with high accuracy. 30 sets of data can be archived for easy and quick adjustment. Compact structure, space saving, and low working voice. Using touch screen CNC to adjust the size of crimping, facilitating debugging and data recording.

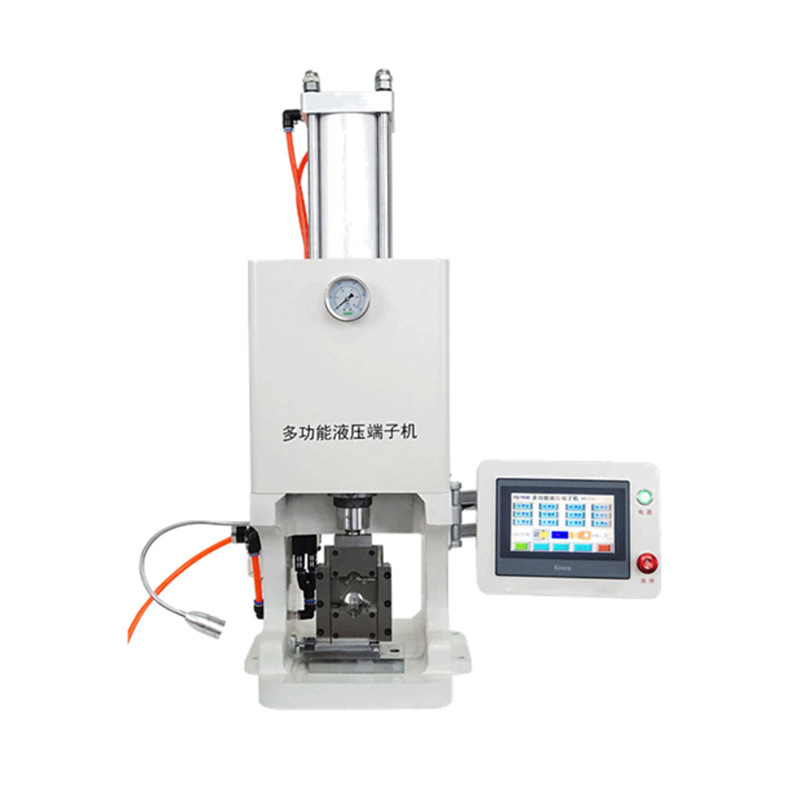

Multifunctional hydraulic terminal machine WZ-570

No need to replace the mold, using variable frequency servo technology, electronic positioning, no need to change the tool, instantly changing the size of the crimping blade, high accuracy, convenient and fast adjustment for 15 sets of data archiving. Compact structure, space saving, and low working voice. Using touch screen CNC to adjust the size of crimping, facilitating debugging and data recording.

Hexagonal mold free hydraulic terminal machine WZ-535

This model can be equipped with hexagonal and four point molds, suitable for various closed tube terminals, open terminals, etc

2. Hexagonal crimping does not require changing the mold. The 6-35 square meter terminal is universal for one machine and can store commonly used processing data. Simply click on the screen and switch with one click

3. Processing data adjustment, crimping height adjustment on the screen, precise and efficient

4. All machines are pre stored with processing data of 6-35 square meters before leaving the factory, which can be adjusted according to actual needs