Fully automatic wire twisting and soldering terminal machine (sheathed wire)

Integrating cutting, peeling, pressing, and twisting with tin, the front end adopts a xy axis double guide rail design for translation, precise docking to ensure the quality of wire stripping and pressing. The rear end peeling adopts a precision screw double guide rail device from Mitsubishi, Japan, for precise peeling; Computer numerical control automatic completion, simple operation, fast speed, high accuracy, and stable performance. Automatically receive terminal waste paper, cut off terminal waste, and automatically alarm for abnormalities.

Keywords:

Automatic

Classification :

Description

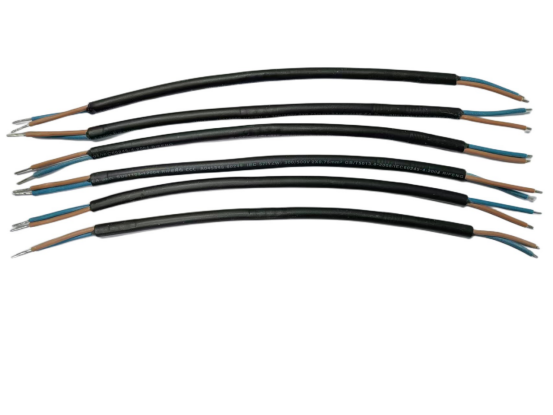

Effect show

| Product name | Automatic twisted wire dipping terminal machine (sheathed wire) |

| Processing range | 0.3-0.75mm round flat sheath wire, two-core, three-core, four-core |

| How it is displayed | Color LCD touch screen |

| Mode of operation | Automatic run + manual run |

| Cutting speed | 1000 strips/hour (length within 100mm) |

| Cut length | 30mm-9999mm |

| Weight | 500KG |

| Power supply | AC220V 50/60Hz |

| Exterior dimensions | 1750*700*1500 |

| Maximum pressure | 2T optional |

| Terminal machine | Cast precision terminal machine |

| Pan mode | Servo screw brake |

| Function | Set cutting wire stripping, pressing end, twisting wire tin in one, the front end translation adopts xy axis double guide rail design, docking precision to ensure the quality of stripping and pressing end, the rear end stripping adopts precision screw double guide rail device Japan Mitsubishi servo, peeling accurate; Computer numerical control automatic completion, simple operation, fast speed, high precision, stable performance. Automatically receive terminal waste paper, cut off terminal waste, and automatically alarm for abnormalities. |

| Detection device | 1. Whether the terminal is there 2. Whether the wire is there or not 3. Crimping test 4. Air pressure detection |

Related Products

Get a free product quote

Our staff will contact you within 24 hours (working days), if you need other services, welcome to call the service hotline: 13925358026